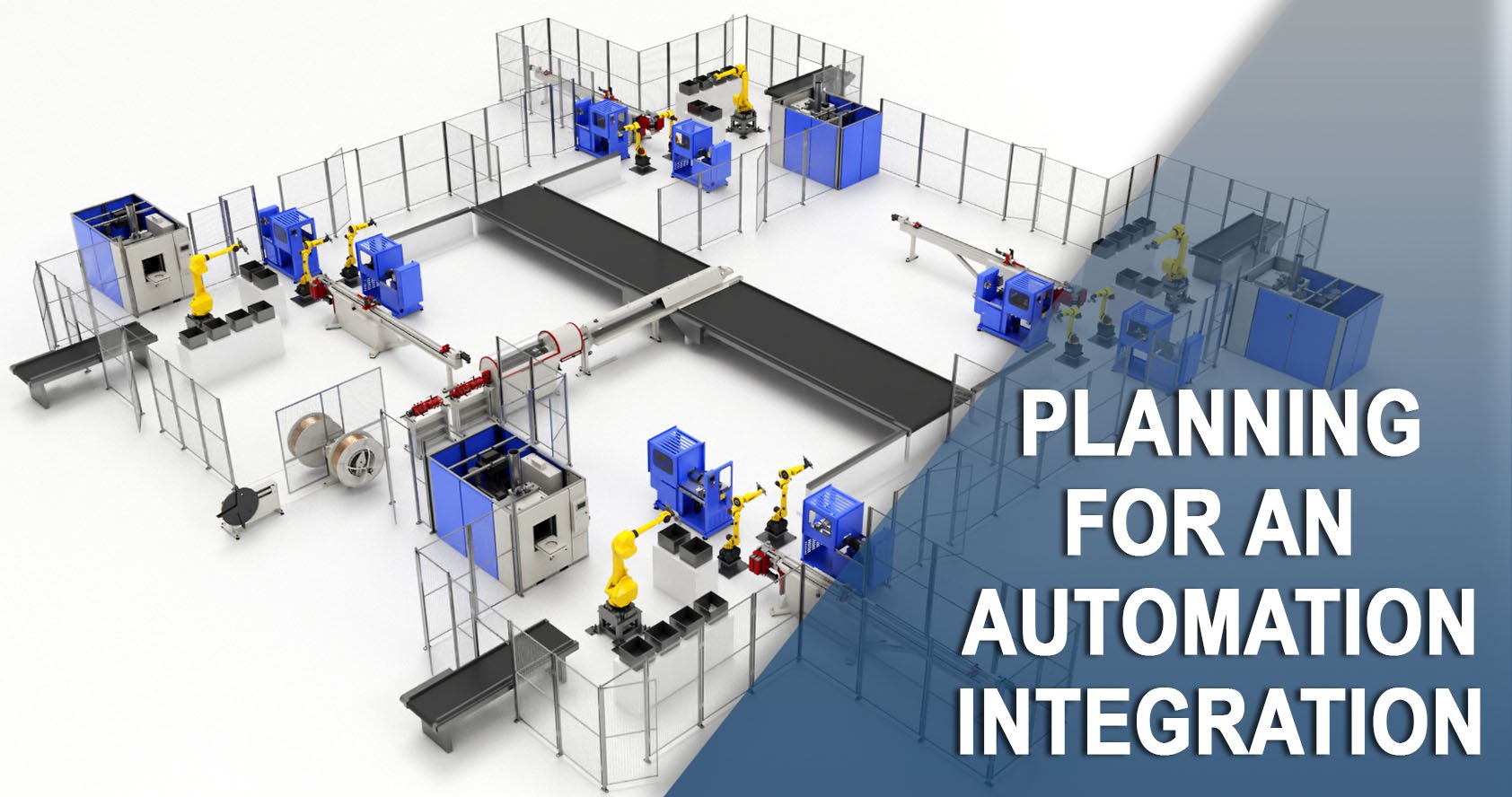

Finding the right partner for large or complex precision machining projects can be challenging. Many precision machining shops are either priced too high, have long lead times, only cover part of the process, or lack the capabilities to scale up for mass production.

Ultimately, you need a partner that can do it all, from initial prototype to large-scale production. This is especially important for projects that require multiple machine types or parts.

.jpg)

.jpg)