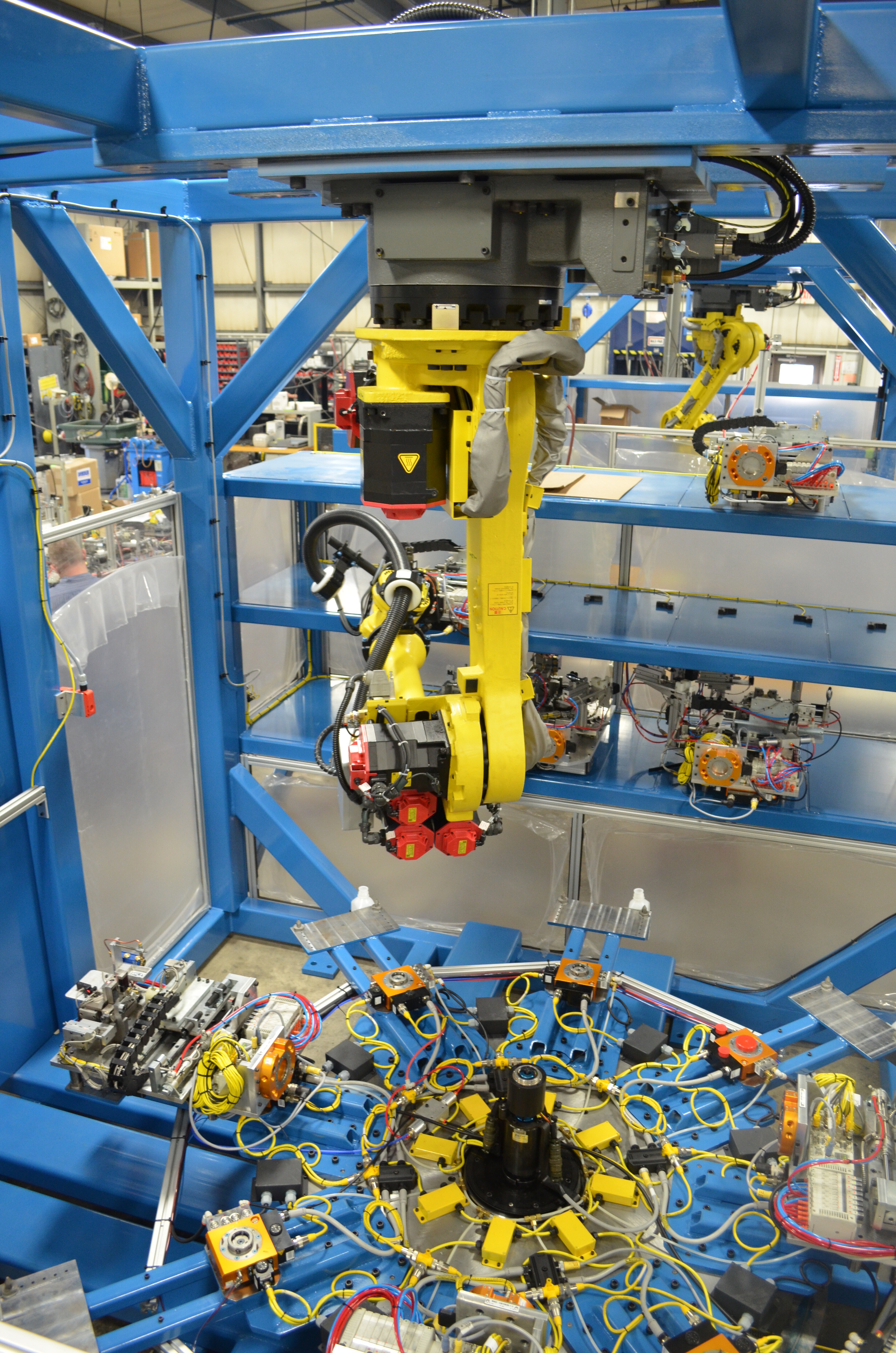

Wauseon, OH: Wauseon Machine, a leading provider of automation solutions, tube forming technologies, precision machining and fabrications, highlights its Redeployable Automation Module, a transformative solution designed to enhance automation efficiency across industries. Engineered for versatility and cost-effectiveness, this platform integrates seamlessly into various manufacturing processes, offering flexibility from manual to fully automated operations. Its modular design allows for easy customization and redeployment, adapting to changing production needs such as assembly, sorting, testing, and handling tasks.

Innovative Solution for Streamlined Production and Flexibility Across Industries - Redeployable Automation Modules!

Recession-Proofing Your Business with Automation: A Strategic Approach

By: Scott Anair, President and CEO of Wauseon Machine

A look at how 2D & 3D Machine Vision increases efficiency

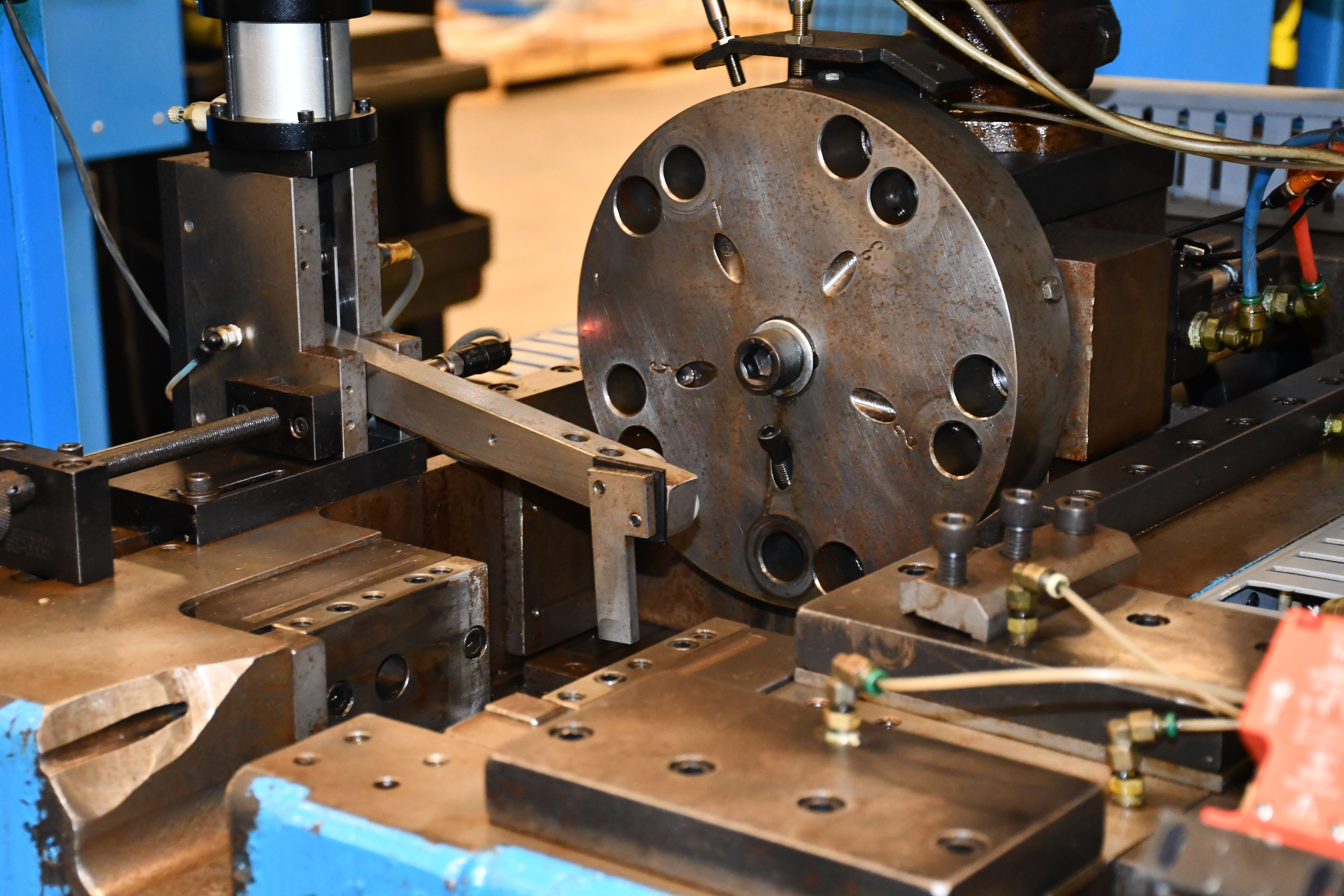

The Longevity & Versatility of Wauseon Machine’s End Forming Equipment

Wauseon Machine’s end-forming equipment stands out for its long-lasting durability and exceptional performance. In an industry where innovation and reliability are crucial, Wauseon continues to set itself apart through the quality of its machines, which are designed to stand the test of time.

Celebrating Excellence: Joe Gemma Receives Prestigious Robotics Award

Wauseon Machine, a leading provider of automation solutions, tube forming technologies, precision machining, and fabrication, is proud to announce that Chief Revenue Officer (CRO), Joe Gemma, was awarded the prestigious Joseph F. Engelberger Robotics Award for 2024, recognizing his exceptional leadership and contributions to the automation industry.

Navigating the Future: Insights on Post-COVID Automation Trends

At the early stages of the COVID pandemic in April of 2020, Joe Gemma, Chief Revenue Officer of Wauseon Machine, penned the piece below.

The Critical Role of Preventative Maintenance in Robotics

In the rapidly advancing world of automation and robotics, the importance of preventative maintenance cannot be overstated. With the increasing reliance of industries on robotics for precision, speed, and efficiency, ensuring these machines operate without unplanned downtime is pivotal. In this light, preventative maintenance emerges as a crucial strategy for maintaining operational continuity, optimizing performance, and prolonging the lifespan of robotics investments.

Wauseon Machine to Showcase Integrated Automation Solutions at Automate 2024

Wauseon Machine to Showcase Integrated Automation Solutions at Automate 2024

Wauseon Machine fabrication services provides an “easy button” procurement process for complex assemblies, in which experts manage the entire value chain, from cradle to grave. From receiving the order, to obtaining raw materials, to handling all necessary heat treating, coating, laser cutting, and stamping processes, Wauseon ensures that fabrication is completed to exacting specifications and that the highest quality product is delivered. Application engineers have years of experience taking large complex assemblies and breaking them down to their component parts. With specialized expertise in providing suggestions on cost avoidance and design for manufacturability, Wauseon experts can often suggest options that may eliminate an operation or use different coatings to improve a product.

Swiss Style Machines Decrease Overall Cycle Time for High Volume Machining of High Quality Parts

High volume machining of complex precision parts poses many challenges. Standard CNC lathe and milling operations can result in high cycle times and labor costs and may not meet precision tolerances. Use of newer Swiss style machines allows operators to process all sides of the part in one operation, significantly lowering costs. These Swiss style machines are very compact compared to standard lathes; less time wasted going from tool to tool can also result in faster cycle times.

.jpeg)