Technology is everywhere. When it comes to staples in your life like your smartphone, your TV, or...

Planning for 2022: How to Approach People & Planning for a Lucrative Automation Integration

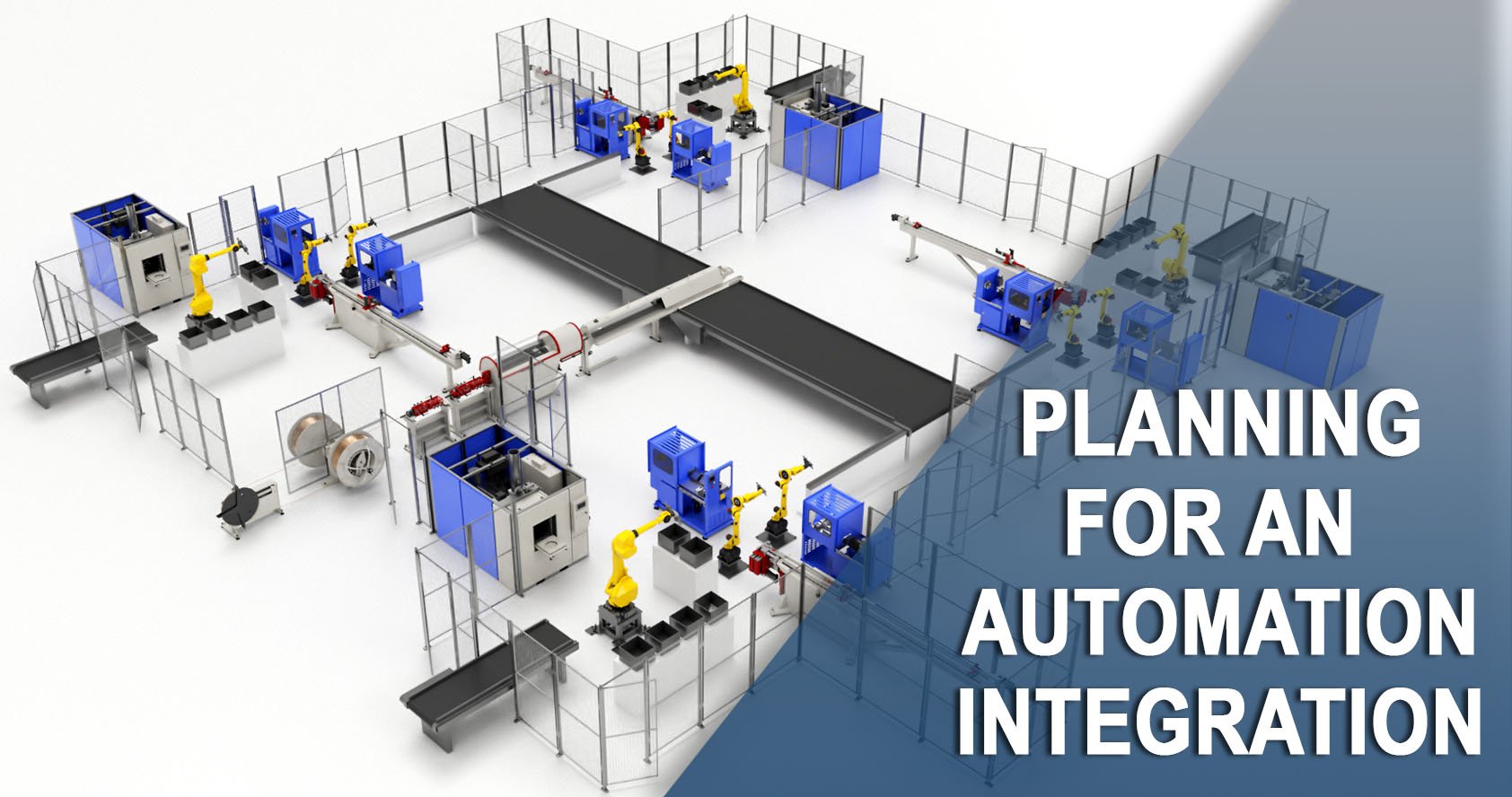

For an investment in automation to be worthwhile and profitable, there’s a particular way to approach the process that involves smart decisions and strategic moves. Whether a manufacturing executive follows this wisdom has a direct impact on their ability to integrate automation solutions that enable the company to perform better, faster, more inexpensively and with greater value to both consumers and investors.

Here, we’re highlighting some of the most critical information and insight to support executives as they begin the process of automating their manufacturing operations. Leverage the following people- and planning-related tips to create a path to automation that maximizes success for you and your organization.

Investigating Options for a System Integration Partner

An essential and primary component of the decision-making, strategy, and planning process involves an automation audit. To get the full value and benefit of an effective automation audit, it’s in the company’s best interest to partner with an expert system integrator—one that has a wealth of experience in your particular area of business.

The importance of this partnership can not be overstated, given the highly complex process of designing and building an automated system suited perfectly for your manufacturing requirements. Even if you have an in-house engineer (or a team of them), it’s unlikely they possess the breadth of knowledge and skill to fully coordinate and carry out a safe and successful integration plan.

Keep in mind that this effort encompasses so much more than purchasing the actual machinery or equipment used to automate the process. Managing the complicated logistics of your entire interconnected system requires the kind of expertise that only a dedicated integration specialist—with experience in your specific line of work—can provide. If your company consists of a welding house, for instance, you wouldn’t want to rely on a company that doesn’t have experience designing automated welding solutions.

Working with an integrator that doesn’t feature the necessary experience may make the price seem more appealing, but you risk ending up with a process that doesn’t meet your requirements or a stalled implementation timeline and future complications that come with an unexpected price tag. Investigate your options thoroughly by checking out supplier directories at industrial trade organizations like the Association for Advancing Automation (A3).

Involving the Right Team of People

In addition to teaming up with an experienced integration partner, it will be paramount to ensure that the process is guided internally by a well-defined leadership team. The smoothest automation integration projects are the ones that align with an internal group consisting of the following contributors:

- A P&L leader

- An operations leader

- An engineering leader

With each of these bases covered, you have the ability to detail capital and budget realities (and get the checks signed), incorporate a deep understanding of the business’s manufacturing operations and refer to the technical savvy of someone who will run the system.

Your automation integration is going to have rippling impacts on both the people on the ground and the business as a whole. That’s why it’s so important to consider each aspect of the project and assign an experienced point person to handle information gathering, communication, interaction with the integration company and supplier, etc. You want the most critical functions involved in the planning and operating of the automated system to be represented as well as possible, and a dedicated leadership team is the ideal solution.

It’s also critical to ensure that the members of the leadership team are all aligned in their goals. In other words, is everyone on the same page with regard to capital spend, ROI requirements, operational improvements and so forth? Having the leadership team in agreement on these goals and expectations is absolutely vital to getting the project off the ground and implementing your automation system successfully.

Getting Clear on Implementation Plans

With a solid integration partner and leadership team in place, it’s time to start hashing out the details of the plan. With new solutions and processes on the way, there are likely to be some necessary considerations in the way of managing downtime and accounting for process changes.

If you’re automating existing equipment, there will be a period of time when the automation needs to be installed, possibly rendering the equipment unavailable for production. The length and scope of this downtime really comes down to the specifics of the automation project. It could be anywhere from a weekend-long delay for simple implementation to over a month’s worth of designing and connecting a large, complex system.

If you’re bringing in a completely new automation system to either replace what exists or create new capacity, the period of time needed for installation is likely to be less lengthy or disruptive in nature.

As you work with the integration partner to hammer out these details, there should also be adequate discussion around issues like the automation system’s life span and flexibility for future retooling. These are elements that the experts will need to factor into the design of the machine(s). You should be aware of how factors like use, maintenance, and environment will affect the life expectancy of your automated systems, and get a clear idea of how they might impact your need for parts replacements or other updates over time.

The key to planning ahead for all of these realities is understanding the customization involved in your integration plan. You’ll need to work with your leadership team and integration specialist prior to installation in order to design a scheme that makes sense for both the business and the integrator.

Success Stems from Smart Strategy

In order to be successful now and into the future, modern manufacturers are charged with staying at the forefront of technology and making smart, strategic decisions that keep improving business outcomes. Current realities have shown us that the time for planning for the future of automation is gone; now manufacturing executives must act and implement to stay relevant and profitable. As you navigate this process, be sure to keep strategy at the helm of any automation project you embrace and take a well-informed approach to implementation.

.jpg?height=200&name=Blog%20Post%2013%20-%20Banner%20Photo%20-%20FINAL%20(1).jpg)